Cuplock Scaffolding – Uses, Types, Benefits, and Safety

Dependable and flexible support is essential to sustain construction and infrastructure projects. And Cuplock scaffolding is that support. Builders, contractors, and project managers all make use of this construction accessory. They know that nothing comes close to Cuplock when we talk about its safety, flexibility, and dependability. Cuplock scaffolding provides a solid foundation for buildings. They are best for industrial or high-rise ones, as well as bridges. If you understand how cuplock scaffolding works, you will be better at managing your projects.

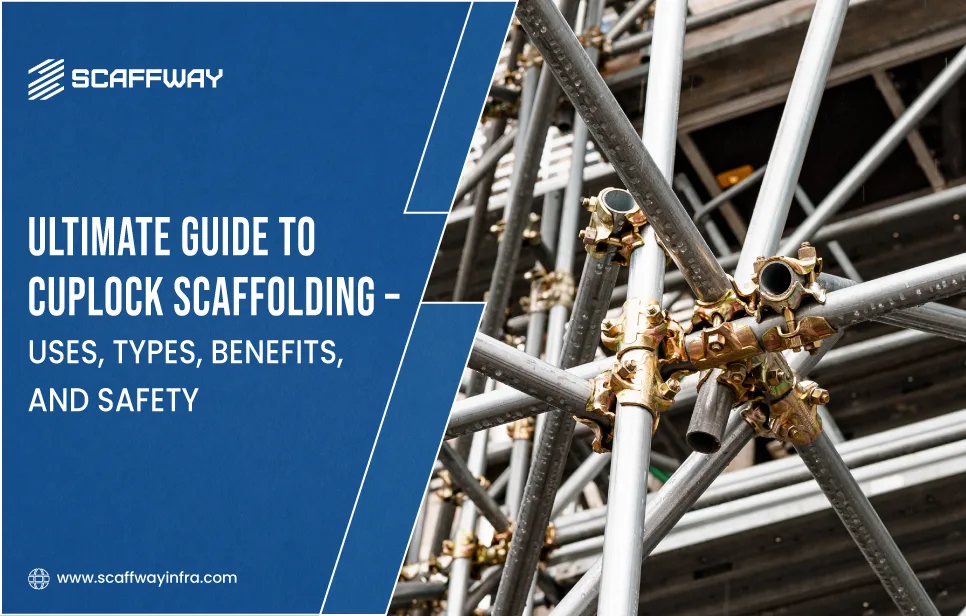

What is Cuplock Scaffolding?

The Cuplock Scaffolding System provides modular scaffolding solutions with a patented circular cup connector. With this innovative design, different horizontal parts can be safely connected to vertical supports. And what you get is a strong and stable system. Unlike more traditional types of scaffolding, which typically utilize loose components and wedges, the Cuplock System has been designed using a simple but effective lock mechanism that requires only a hand-held hammer to secure.

They are useful for contractors and companies looking for dependable scaffolding solutions. The Cuplock System provides an option that is constructed of galvanized steel. This feature gives it a long lifespan and protects it against extreme environmental conditions. There are numerous companies like Scaffway that provide A-plus cuplock scaffolding. Our product satisfies the requirements of the construction industry and complies with international standards.

Types of Cuplock Scaffolding

If you want to use the right type of cuplock scaffold for your specific needs, it is important to understand 5 types of cuplock scaffolding:

- Standard Access Scaffolding

The most common type, standard access scaffolding, consists of cuplock vertical standards placed on fixed bottom cups at regular intervals. The verticals form the backbone of the main structure. This is designed to support the ledgers, transoms, and various bracing components.

- Support Scaffolding

Support scaffolding was specifically engineered to carry heavy loads. It is perfect for supporting formwork and other structures where significant load-bearing capacity is required. This type of scaffolding utilizes reinforced standards and heavy ledgers to enable its high load-bearing capacity.

- Mobile Tower Scaffolding

Mobile tower scaffolding has wheels with casters. This allows for flexibility and convenience. These two factors help in working on projects that need to be quickly moved from one place to another. Mobile tower scaffolding is also great for performing maintenance tasks. It works well indoors and in confined spaces.

- Staircase Towers

Staircase towers are a specialized configuration of scaffolding. It incorporates steel stair stringers and treads. They allow personnel to safely access. They give ease to them to work at different levels of the tower.

- Loading Towers

Loading towers are outfitted with reinforced platforms and extra bracing. This provides increased stability while being used to store and transport materials on a construction site.

Benefits of Cuplock Scaffolding

Cuplock scaffolding is ideal for any kind of construction project. One great thing about Cuplock support is how quickly it can be put together. Cuplock is also better in the following ways when it comes to safety, flexibility, durability, and load-bearing capacity:

Speed of Assembly—With the patented cup-and-blade locking mechanism of Cuplock scaffolding, there is no need for additional accessories such as bolts or loose connections, allowing for quick and easy setup/dismantling of the scaffold system on job sites due to its simplicity in design.

Enhanced Safety— The positive lock design of the cuplock scaffold connecting heads provides easy installation of couplers or tubes. There is no possibility of accidental loosening during use. This ultimately eliminates the risk of falling objects. At the same time, it ensures structural soundness.

Versatility—Because the cuplock scaffold system is modular, it can be used for a lot of different kinds of support. This includes access platforms and complicated apps for supporting structures.

Durability—The hot-dip galvanized covering on Cuplock scaffolding keeps the steel parts from rusting. This makes the Cuplock last longer on building sites in the long run.

The Cuplock scaffold system's rugged design features have enabled it to support significant vertical loads. It makes it useful for easy access. Apart from this, it's good for heavy-duty scaffold support applications.

Cost Savings—The initial costs might be greater than some other alternative scaffolding systems. But keep in mind the long-term economic benefits of reusing or recycling Cuplock scaffolding materials are great. The reduced labour costs that come with the setup and takedown of Cuplock scaffolding mean that Cuplock is ultimately the best choice for value in scaffolding projects.

Safety Considerations

The cuplock scaffolding system is designed with safety features; however, it is imperative that proper procedures are followed:

Before Erection—

1) Perform a ground assessment to determine if the area is capable of supporting the weight

2) Design the scaffold based on both the needs of the project and the load calculations

3) Inspect all parts of the cuplock scaffolding for signs of damage, deformation, or excessive wear;

4) Ensure that you have received certifications from all cuplock scaffolding manufacturers, that are still valid

During Assembly—

1) Use only trained and certified scaffolders to erect or modify any scaffold structure;

2) Level the base with the adjustable jacks

3) Place diagonal braces as specified in the design

4) Make sure that every cuplock is correctly engaged and secured

5) Put on guardrails, toe boards, and any other type of fall protection.

During Use—

1) Do not exceed the estimated load capacity of the scaffold

2) Check the scaffold regularly (especially after bad weather)

3) Do not make alterations without obtaining the appropriate authorization;

4) Require that everyone who uses the scaffold wear the appropriate personal protective equipment;

5) Keep the exit and entrance routes clear and open.

Dismantling—

1) Dismantle the scaffold in reverse order of how you erected it

2) When removing parts from the scaffold, be sure to lower them using the correct type of hoisting equipment and never throw parts down;

3) Inspect, clean, and stock all scaffolding components before they are put into storage

4) Report any broken items that require repair or replacement.

Conclusion

The Cuplock Scaffolding System includes all the parts needed to build safe, efficient, and flexible scaffolding for today’s construction work. It offers great flexibility for building many types of commercial and industrial structures. These scaffolds are important for building and maintaining public infrastructure projects.

While Cuplock scaffolding has many uses, having the right accessories and equipment is key to making sure your project goes smoothly. Working with a trusted scaffolding rental company gives you all the parts and services you need to finish your work.

If your project needs safe, flexible, and dependable temporary access systems, come to Scaffway. Our scaffolding rental services in Hyderabad offer both long-term and short-term options to fit your needs.

Connect With Us

We’re here to help you with all your scaffolding and access solution needs. Whether you have a query, need product information, or require a customized solution, our team is just a call or message away. Reach out to us through phone, email, or by filling out the contact form, and we’ll get back to you at the earliest.