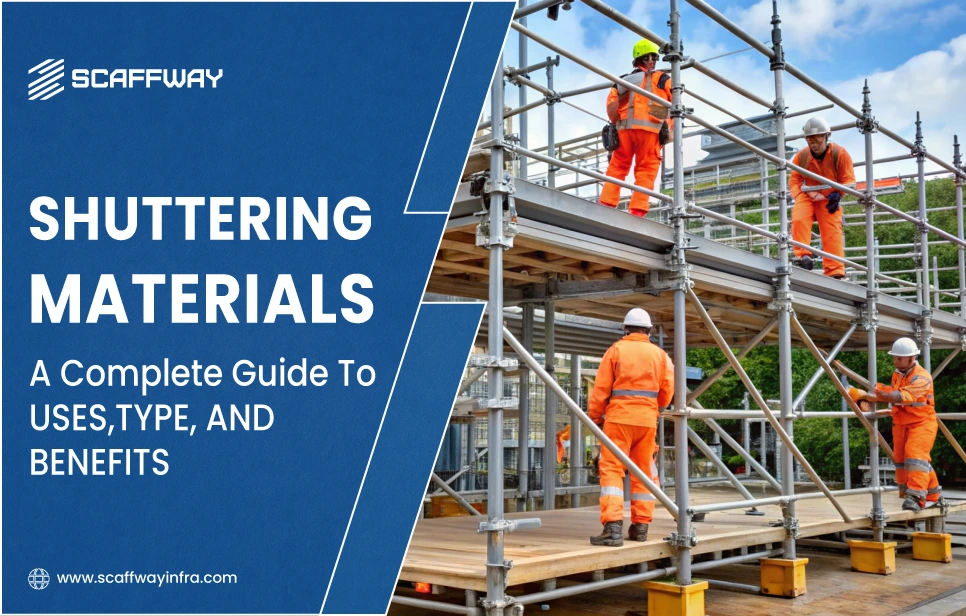

Shuttering construction is key to modern construction when forming concrete structures and ensuring their sustainability. If you work on a scaffolding large construction project or in residential construction, understanding shuttering material is important for achieving quality project outcomes and efficiencies.

What is Shuttering Construction?

Shuttering construction is the temporary framework or mold. Its work is to support the concrete until it sets and gains sufficient strength. They are very important for building walls, blocks, beams, and columns. These structures need to have the right dimensions and smooth finishes. And Scaffway, an experienced shuttering construction company in India, provides you that. We offer better-quality material than the rest in the market. We also help you with your work by giving you professional advice.

Types of Shuttering Construction

It's quite important to keep familiarity with different types of shuttering. This will also assist contractors in determining what may be best in each situation:

Timber Shuttering: The first and most traditional type of shuttering is timber. Timber is flexible in being able to create custom shapes. But timber has a shorter lifespan than the types that follow, and it requires maintenance.

Steel Shuttering: Steel shuttering is very durable and can be reused many times. Steel shuttering has the best finish. It is capable of sustaining more use. This quality makes it something you might want to consider for large-scale projects. Another factor to note is that it is often cost-effective.

Plywood Shuttering: Plywood shuttering is lightweight and strong. They create an excellent, smooth concrete surface while maintaining greater strength than traditional timber. It's more convenient to work with also.

Aluminum Shuttering: A more modern option, aluminium shuttering is lightweight. And did we mention it is corrosion-resistant? Well, it is. These shuttering assemblies also go together fairly quickly. They are convenient for repetitive architectural elements.

Plastic Shuttering: Plastic shuttering is increasingly popular among small and medium projects. They are lightweight and water-resistant. And also, cost-effective.

Essential Shuttering Components

There are a number of specialized shuttering components in use. Their work is to make our construction more efficient:

U Jacks for Shuttering: An adjustable support system that provides height adjustment and stability. U jack for shuttering are essential in levelling. It's the best tool for supporting forms at different heights along the vertical. They keep the forms in alignment while pouring concrete, ensuring that the concrete is placed accurately.

Prop Shuttering: Props, or adjustable supports, bear the weight of the shuttering platforms. If considering either exporting prop shuttering for international projects or sourcing locally from prop shuttering manufacturers, the backing provided by the props is critical for vertical and horizontal support during construction.

Shuttering Plates: As produced by the leading shuttering plate manufacturers, shuttering plates are the material that faces the concrete generally, serving as its primary contact surface. A quality shuttering plate will yield a smooth finish and can also be reused several times, which again reduces the overall cost of the project.

Acro Span systems: Acro Span shuttering manufacturers in India produce adjustable beam systems that provide flexible support for slab formwork. These systems continue to demonstrate design for the purpose of safety but do allow for the support of slab shuttering to different heights and spans.

Benefits of Quality Shuttering Materials

Quality matters a lot in this business. There are many benefits to purchasing a premium shuttering material. Scaffway, in this case, is a leading shuttering material manufacturer in Hyderabad, India. The benefits include:

Improved Safety: Quality shuttering systems can minimize the risk of structural failure while pouring concrete. This is beneficial to the workers as well as the host structure.

Long-term cost savings: The most important point is that more durable materials can be reused across multiple projects. This results in significant savings in applied costs for the project over an extended period.

Reduction in project time: Your project is saving on time due to modern-day shuttering systems. It allows for easy assembly and disassembly processes. This makes construction time shorter.

Outstanding finish: The finishing work should be of higher quality. Good formwork typically addresses this. The one associated with exposing the concrete surface.

Accuracy of structure: Potentially beneficial impact on the accuracy of the dimension is ensured through accurate shuttering, which is significant for the overall aesthetic appeal and structural integrity of a project.

Conclusion

Shuttering is an essential component of all large and small construction projects, which include scaffolding, to get quality concrete work done. Each contractor should understand the various types of shuttering and the different materials that are available when looking for quality results. Working with Scaffway will also ensure that you are delivering on a project that you can be proud of. Something that exemplifies everything your client would want in a project by upholding the highest standards of safety, efficiency, and quality.

If you are an owner-builder, contractor, or project manager and are looking to get the shuttering material for a project, Scaffway is your answer. We are a reputable company that will give you the best return and outcomes from your project, which will ultimately save you from cost overruns.

Connect With Us

We’re here to help you with all your scaffolding and access solution needs. Whether you have a query, need product information, or require a customized solution, our team is just a call or message away. Reach out to us through phone, email, or by filling out the contact form, and we’ll get back to you at the earliest.